Services

We understand the automation need, its own challenges, solutions and methodology for Manufacturing (End User) and OEM (Original Equipment Manufacturer) segment. We adopt two distinct strategies to handle each segment need efficiently.

Manufacturing Industries (End User):

The different plants & production facilities have different levels of automation maturity, need, different process/operational problems to solve. Our team has vast experience and knowledge to deep drive into your various process, operational areas to surface out exact pain points, key business decision making criteria. We design & suggest the solution to address the identified pain points to achieve overall equipment efficiency (OEE), increase productivity/yield, improve uptime, minimum downtime, maximum predictive maintenance data etc.

OEM:

We are supporting our OEM customers to deliver smart, and innovative machines/skids that meet their specific needs and that can help them compete globally.

Our team understands the stringent requirement of the automation system while designing it for OEM.

Machine Integration/Plant Integration System

Efficient production is one of the fundamental drivers of profitability in any industry. Plant-wide integration consists of seamless data flow between various control systems/devices/machines to exert tighter operational control through various process areas. The central control system/server provides a common database for richer insights and key business decision-making KPIs.

NextGen’s solution is an innovative, modern approach to the challenges faced by companies in the manufacturing domain. It brings in a new era of increased efficiency, reliability and profitability at various levels of operation.

NextGen’s customised plant-level Integration solution works by integrating the control systems provided by OEMs (Original Equipment Manufacturers) at the line, machine and process levels. It also provides a common control system platform which integrates various PLC/control systems operating over different communication protocols.

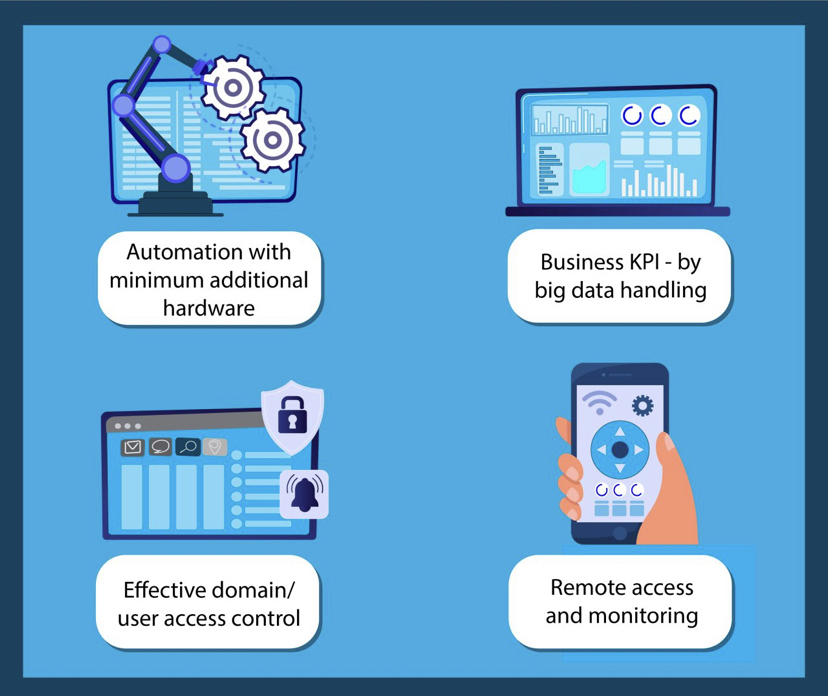

Our centralised/integrated architecture offers the following benefits:

- Efficient, uniform processing of operational data with high accuracy levels

- Remote monitoring and tracking

- Optimising machine operations (performance levels, spin up and shut down etc.)

- Boosting Overall Equipment Effectiveness (OEE)

- Faster troubleshooting and reduced downtime

- Lower wastage and higher yield

- Centralised data for key business decision making

A digital-first approach, including interfacing with IIoT (Industrial Internet of Things) devices, big data handling capabilities and the ability to handle multiple communication protocols while providing a common interface to the users, allows manufacturers to stand out from the competition in many ways, be it shorter delivery times, increased availability, or facilitating seamless integration into a higher-level automation system.

So, what are you waiting for?

Contact our experts today.

Predictive Maintenance -Motor Condition monitoring

The costs of scheduled or unscheduled downtime in manufacturing environments can be detrimental to operations. Avinya makes it easy to monitor equipment health in real time and predict failures. We deliver insights organizations need to avoid machine failures and unplanned downtime, increase equipment and production line productivity, and reduce maintenance costs.

Our scheduled maintenance inspections have been developed and improved through years of automation system maintenance experience. Pending system failures are identified and only those system components that are past their operational lifecycle are recommended to be repaired or replaced. This approach drives down costs by eliminating unnecessary repairs occurring with most time-based preventive maintenance programs.

Business Analytics: SCADA based Reporting solution.

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces (GUI) for high-level process supervisory management.

with our Advanced Distribution Management System and Outage Management Systems being instrumental in helping you to make smarter and better-informed distribution and network decisions. Our SCADA and Information Software is designed to be a robust and flexible solution for utilities, water & waste water , oil and gas whilst our design and operational data systems offer increased workflow efficiency for your engineers.

End to End Product Tracking: Integrated Barcode / QR code management System.

Easily identify all the items when receiving, consuming, or counting inventory

When it comes to updating your inventory, barcode scanning is the optimal solution in terms of time and accuracy. Barcode inventory software automates the flow of information from factory to warehouse to sales to shop floor, making it easy to identify multiple items and keep track of availability to avoid stock outs.

- Scan and receive items using a smart device

- Simplify stocktaking and inventory counting

- Scan a range of barcodes, including supplier item codes, internally registered barcodes, and batch barcodes